We chose Kulim Hi-Tech as a location to make our operation because this location offers an expanding and bing installation alternatively of holding to travel, keeping current sites while adding another installation elsewhere and shuting the bing installation and traveling to another location.

Kulim hi-tech park, besides known as ‘Science City of The Future’ High-tech Industrial Park is the first in Malaysia. Hi-Tech Industrial Park Kulim is located in North-South and East West in Kulim District, in the South of the State of Kedah Darul Aman. Hi-Tech Industrial Park is connected to the port of Penang which is about 25 kilometers further east. This location is besides connected to the Penang International Airport which is located following to the island about 40 kilometers off.

- Labor Productivity

When make up one’s minding on a location, direction may be tempted by an area’s low pay rates. Management must besides see productiveness. Toplicious Sdn Bhd has a few options of low rewards rates place to run. There are few topographic points that offer low rewards rates like Shah Alam, Selangor and Seberang Prai, Penang. We had 3 potency placed which are Kulim Hi-Tech, Shah Alam and Seberang Prai. We expect the all three topographic points can bring forth same unit production per twenty-four hours ( 1000 unit ) but that differentiate these three countries are labour costs per yearss. Labor cost per twenty-four hours is RM 40 for Kulim Hi-Tech, RM 60 for Shah Alam and RM 50 for Seberang Prai.

|

Kulim Hi-Tech |

Shah Alam |

Seberang Perai |

|

RM 40= RM 0.04 1000 |

RM 60= RM 0.06 1000 |

RM 50= RM 0.05 1000 |

After making the computation, Kulim Hi-Tech is the most economical placed to bring forth cocoa comparison with Shah Alam and Seberang Perai. So, Kedah is the site that Toplicious Sdn Bhd can construct the mill. Besides, revenue enhancement imposed by the authorities of this state is low compared to the two other provinces.

- The Factor-Rating Method

Factor-rating method is a location method that instills objectiveness into the procedure of placing hard-to evaluate costing. The factor-rating method is popular because a broad assortment of factors, from instruction to reaction to labour accomplishments, can be objectiveness included. The factor-rating method has six stairss:

- Develop a list of relevant factors called cardinal success factors.

- Delegate a weight to each factor to reflect its comparative importance in the company’s aim.

- Develop a graduated table for each factor.

- Have direction score each location for each factor, utilizing the graduated table in measure 3.

- Multiply the mark by the weights for each factor and entire the mark for each location.

- Make a recommendation based on the maximal point mark, sing the consequences of quantitative attacks every bit good.

|

Key Success Factor |

Weight |

Tonss ( out of 100 ) |

Weighted Mark |

||||

|

Kulim Hi-Tech |

Shah Alam |

Seberang Perai |

Kulim Hi-Tech |

Shah Alam |

Seberang Perai |

||

|

Technology |

0.20 |

90 |

80 |

75 |

18 |

16 |

15 |

|

Labor handiness and attitude |

0.15 |

75 |

80 |

75 |

11.25 |

12 |

11.25 |

|

Political and legal facets |

0.15 |

80 |

75 |

75 |

12 |

11.25 |

11.25 |

|

Social and civilization facets |

0.20 |

75 |

65 |

75 |

15 |

13 |

15 |

|

Environmental factors |

0.30 |

85 |

70 |

75 |

25.5 |

21 |

22.5 |

|

Entire |

1.00 |

81.75 |

73.25 |

75.00 |

|||

We can reason that the highest mark earned by Kulim Hi-Tech instead than Shah Alam and Seberang Perai. These factor evaluations give strong ground why the organisation decided to do their mill at Kulim Hi-Tech.

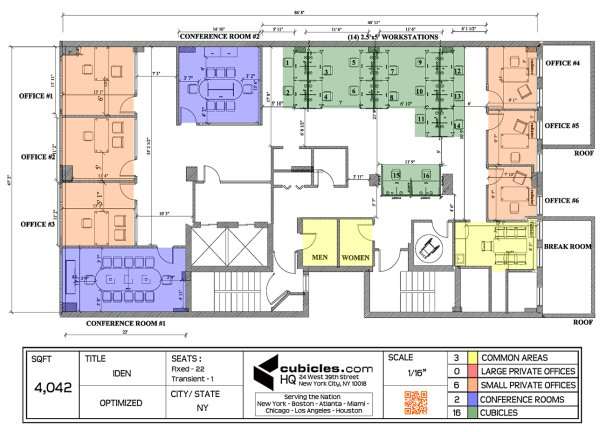

- Layout Decisions

Layout determinations will find the long tally efficiency of operation. Directors make layout determinations to accomplish a to the full use of infinite, equipment and people, improved information flow, improved employee and client interaction and flexibleness. There are three types of layouts which are the office layout, warehouse layout and workcell layout.

The office layout is indispensable for every company, because it is the lope of the motion of information, grouping of workers and their equipment and infinites to supply comfort and safety. First, examine electronic and conventional communicating forms, needed for separation and other conditions act uponing employee effectivity before doing a determination sing the layout scheme.

Toplicious Sdn Bhd needs to hold an office that considers three physical and societal facets which are propinquity, privateness and permission. Proximity is the fact that the infinites should of course convey people together. Peoples can command entree to their preservation including the privateness facet and the civilization should signal, that non-work interactions are encouraged.

The staff of Toplicious Sdn Bhd that should be in the office is the CEO, COO and CFO, the secretary and all sections needed, such as a production section, accounting section, selling section, gross revenues section and so on. Furthermore, cardinal files, transcript Centre, larder and all necessities need to be in the office edifice. The layout of the office is designed with taking consideration of the hierarchy of the company. The Chief executive officer and all main sections are in one topographic point but with different suites. Furthermore, the main section is placed near the other staff in the section. Besides we took consideration of the necessities of the section like e.g. the accounting section needs to be near the cardinal file and transcript Centre and the secretary office and gross revenues country. Examples of office layouts are below ( taken from Cubicle.com ) :

Second, warehouse and storage layout determination which places that shop the good earlier traveling to other stages. The aim is to happen the optimal trade-offs between managing costs and costs associated with warehouse infinite. Our warehouse is used to have the ingredients like chocolate beans, milk, sugar ( natural stuffs ) and cocoas ( finish goods ) .

Items stored in the warehouse are the undermentioned:

- Cocoa bean

- Milk, chocolate butter and sugar

- Popcorn

- Jelly

- Finish good

Toplicious Sdn Bhd uses cross docking warehouse and storage layout. That means that we ‘re avoiding the arrangement of stuffs or supplies in the storage by treating them every bit shortly as possible. The benefits of this attack are reduced merchandise handling, stock list and mill costs. Toplicious can prosecute a low cost scheme besides a distinction scheme entirely. This requires tight agendas and accurate inbound merchandise designation.

Activities involved in this warehouse are having chocolate beans from the provider and direct them straight to the bean processing topographic point. Then, milk, chocolate butter and sugar from a provider, readily stored in the warehouse is used to bring forth the cocoa when needed. Popcorn and jelly are besides stored in the warehouse and are used in the packaging procedure where the cocoa is filled with the gelatin. For the natural stuffs from the provider, Toplicious Sdn. Bhd. is utilizing a JIT system so that we will have the stuffs from provider merely when we need it.

The standard stuff is so straight sent to the assembly line, as a ground the storage infinite will be reduced. Therefore, a tight agenda is required to manage the motion of this stuff and to guarantee that it will run swimmingly with no mistakes or holds. The last points in the warehouse are the finished goods after the packaging procedure is finished. The labeled cocoa will straight travel to the distribution channel. Formal receiving, hive awaying and order choice activities are avoided.

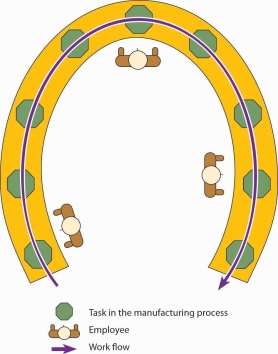

Last, the layout determination is the demand to believe about heightening concern operations with the work cell layout. Work cell layout reorganizes people and machines that would normally be distributed in assorted sections, into groups. Our company Toplicious Sdn Bhd chooses this layout in the production because of the advantage of decreased work in procedure stock list, reduced demand of floor infinite, lower direct labor costs, increased employee engagement and increased equipment and machinery use.

Toplicious Sdn Bhd merchandises are popcorn with milk cocoa in a glass jar, popcorn with white cocoa in a glass jar and milk cocoa with jelly in a saloon. We merely focused on these three types of merchandises so work cell is the best method to be applied in the operation. Different from Beryl’s mill that deem to be implemented procedure oriented layout because there are over 70 different types of cocoas under Beryl’s trade name and they include spirits such as Almond, Butterscotch, Peanut Butter, Raisin, Dark Chocolate, Mint, Tiramisu, Strawberry, and a batch more.

In bean processing operations there are three activities such as chaff separating, roasting nibs and anchoring to liquid chocolate. These three activities are put together in a U form layout. Due to that, workers have a better entree to the operation. For the cocoa operation activities we are polishing the chocolate to waferthin beds and conche the cocoa. These operations are besides put in U form layout. Lapp goes to other stages of operations and this U form layout is shown below:

In decision, layout determination is capable to significant research attempt therefore it depends on what the company thinks is best for the company. For Toplicious Sdn Bhd ‘s layout determination we are planing an office layout, warehouse and storage layout, utilizing cross moorage and work cell layout.

- Conclusion & A ; Recommendations

In a nutshell, schemes such as Product Design, Process Design, Location Decisions and Layout Decisions in Operations Management are applied in the operations of cocoas by understanding the operations to do strategic operations direction determinations. Merchandises are differentiated to hold a competitory advantage. However by building a house of quality we could observe a failing which is the products’ distribution. We recommend increase infinite in retail merchants and more contracts in hypermarkets. The procedure design is extremely automated which means that insistent procedure of bring forthing those three types of cocoas. A flow chart is further used to assist understand, analyze and pass on the procedure. Our location determination is in Kulim Hi Tech as it was the most suited and efficient topographic point to fabricate based on computation of labour productiveness and factor-rating method that we applied. Certain cardinal success factors that we found best fit and relevant to the operations are used in factor-rating method. Toplicious Sdn Bhd ‘s layout determinations are by planing an office layout, warehouse and storage layout, utilizing cross moorage and work cell layout. We found that the layout that we used to the full utilizes infinite, equipment and people, improved information flow, improved employee and client interaction and flexibleness. All these four operation direction schemes that we learned are applied in order to do the best of the operations’ efficiency and effectivity. We found these techniques valuable in turning inputs into end products in the best manner they could.