Trial on Hardened Concrete

This chapter describes the consequences of the trial programmed to set up the mechanical belongingss of the conventional concrete every bit good as GGBFS added concrete with different per centum to the weight of the cement. Concrete mixes detailed in the proceeding chapter. Mixing of ingredient of concrete is done for the mix proportion for M50 class of concrete mixes by adding GGBFS with different per centums 0 % ,10 % ,20 % ,30 % ,40 % ,50 % and 60 % .

Preparation of trial specimen

Cube specimen of size15cmx15cmx15cm, cylinder specimen of length20cm and diameter 10cm, and prism of size 50cmx10cmx10cm were casted. The ingredients of concrete were assorted exhaustively in the sociable boulder clay unvarying consistency was achieved. The specimens were compacted on a vibrating tabular array. The specimens were demolded after 24 hours of casting and cured for 7,14 and 28 days. In the experimental work entire 189 specimens were cast which includes 63 regular hexahedrons, cylinders and prisms.

Tests on Hardened Concrete

Following trials were conducted to find the mechanical belongingss of the concrete

- Compressive strength

- Split tensile strength

- Flexural strength

- Ultrasonic pulsation speed

Compressive strength of concrete

Among all the trial of the concrete compressive strength trial is the upmost of import which gives thought about all the characteristics’ of concrete, and it has a definite relationship with all the other belongingss of concrete i.e these belongingss are improved with the betterment in compressive strength. The size of the mold is normally 15cmx15cmx15cm.concrete regular hexahedrons are tested for 7, 14 and 28days as per IS: 516-1959 ( Part 5 ) .Rate of application burden is 1.40KN/cm2/min.

Compressive strength=

Table-11 Compressive strength of concrete for assorted per centums of GGBFS in N/mm2

| Replacement of ggbfs in % | 7Days compressive strength Mpa |

14Days compressive strength Mpa |

28 days cube compressive strength

Mpa |

| 0 | 39.50 | 46.44 | 50.68 |

| 10 | 37.60 | 45.33 | 51.67 |

| 20 | 35.66 | 47.80 | 52.55 |

| 30 | 34.12 | 43.33 | 49.07 |

| 40 | 33.63 | 39.36 | 45.95 |

| 50 | 31.89 | 36.21 | 42.17 |

| 60 | 30.85 | 34.50 | 39.70 |

Cylinder Splitting Tension Test: This is besides sometimes referred as, “Brazilian Test” . This trial was developed in Brazil in 1943. At about the same clip this was besides independently developed in Japan.Split tensile strength

The trial is carried out by puting a cylinder specimen horizontally between the lading surfaces of a compaction proving machine and the burden is applied until failure of the cylinder, along the perpendicular diameter.

Split tensile strength=

Where:

P = burden applied to the cylinder

D = diameter of the cylinder

L = Length of the cylinder

The loading status produces a high compressive emphasis instantly below the two generators to which the burden is applied. But the larger part matching to depth is subjected to a unvarying tensile emphasis moving horizontally. It is estimated that the compressive emphasis is moving for about 1/6 deepnesss and staying 5/6 deepness is subjected to tenseness.

In order to cut down the magnitude of the high compaction emphasiss near the points of application of the burden, narrow packing strips of suited stuff such as plyboard are placed between the specimen and lading planets of the testing machine. The packing strips should be soft plenty to let distribution of burden over a sensible country, yet narrow and thin plenty to forestall big contact country. Normally, a plyboard strip of 25 millimeters broad, 3mm midst and 30cm long is used.

The chief advantage of this method is that the same type of specimen and the same testing machine as are used for the compaction trial can be employed for this trial. That is why this trial is deriving popularity. The rending trial is simple to execute and gives more unvarying consequences than other tenseness trials. Strength determined in the splitting trial is belived to be closer to the true tensile strength of concrete, than the modulus of rupture. Dividing strength gives approximately 5 to 10 % higher value than the direct tensile strength.

Table-12 Tensile strength of concrete for assorted per centums of GGBFS in N/mm2

| Replacement of GGBFS, % | 7Daystensile strength Mpa |

14Daystensile strength Mpa |

28Daystensile strength Mpa

|

| 0 | 3.95 | 4.95 | 5.10 |

| 10 | 3.76 | 4.56 | 5.17 |

| 20 | 3.58 | 4.38 | 5.30 |

| 30 | 3.21 | 3.96 | 4.34 |

| 40 | 3.07 | 3.35 | 3.85 |

| 50 | 2.93 | 3.12 | 3.72 |

| 60 | 2.80 | 2.98 | 3.58 |

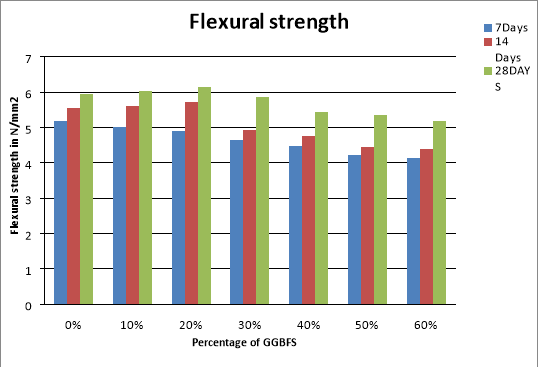

Flexural strength is one of the step of compressive strength of concrete. It is a step of an unreinforced concrete slad or beam to defy failure in bending.It is measured by lading 500x100x100mm concrete beam.The flexural strength is expressed ac modulus of rupture and it is determined by standard trial method ASTM C-78 ( 3rd point lading ) or ASTM (center point lading ) .The flexural strength of concrete is dbout 10-20 % of the compressive strength of the concrete depending on size, type and volume of the harsh sum used. The flexural strength determined by 3rd point burden is lower than the strength determined by Centres point burden.

Flexural strength of concrete

Modulus of rupture =

Where,

P=load applied

L=Length of the prism

B=Width of the of the prism

D=Depth of the prism

Table-13Flexural strength of concrete for assorted per centums of GGBFS in N/mm2

| Replacement of GGBFS, % | 7Daysflexural strength Mpa |

14Daysflexural strength Mpa |

28Daysflexural strength Mpa

|

| 0 | 5.18 | 5.54 | 5.94 |

| 10 | 05.01 | 5.62 | 06.03 |

| 20 | 4.89 | 5.71 | 6.15 |

| 30 | 4.66 | 4.93 | 5.86 |

| 40 | 4.49 | 4.77 | 5.45 |

| 50 | 4.21 | 4.45 | 5.34 |

| 60 | 4.14 | 4.38 | 5.19 |

Ultra sonic pulsation speed

Supersonic pulsation speed is one of the non destructive testing method which provides information about the uniformity of concrete, pits, clefts and defects.The pulse speed in a stuff depends on its denseness and its elastic belongingss which in bend related to the compressive strength and quality of concrete. The trial is carried harmonizing to IS 13311 ( Part1 ) :1992.The experiment’s specific equipment determines the travel clip of an supersonic moving ridge through the concrete specimen between the sender and reciver placed on two opposite sides of the sample.By means of the determined travel clip the wave’s speed can be determined.

Table-14 pulse speed consequences

| Replacement of GGBFS, % | Pulse speed ( km/sec ) | General status |

Quality categorization

|

| 0 | 6.422 | Excellent | Very Good |

| 10 | 4.534 | Excellent | Very Good |

| 20 | 4.901 | Excellent | Very Good |

| 30 | 4.602 | Excellent | Very Good |

| 40 | 4.102 | Excellent | Very Good |

| 50 | 4.544 | Excellent | Very Good |

| 60 | 4.689 | Excellent | Very Good |

RESULTS AND DISCUSSIONS

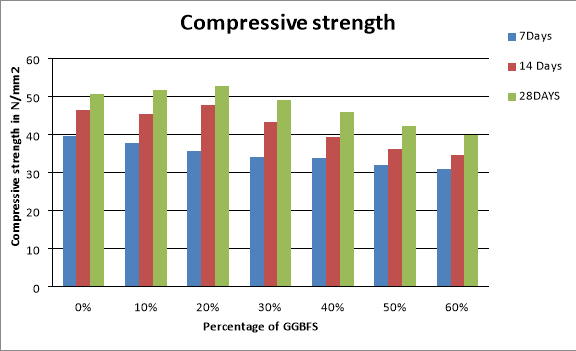

Compressive Strength

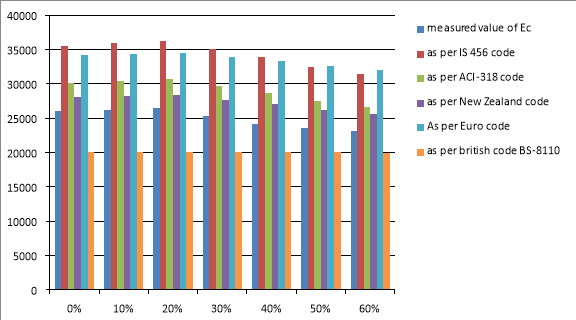

Graph-1 Compressive strength of concrete at7, 14 and 28 yearss

For concrete the chief standards to cognize the mechanical belongingss is compressive strength, in this instance compressive strength trial is conducted for the concrete incorporating assorted per centums of land granulated blast furnace.Here the 7 and 14 yearss compressive strength of the GGBFS concrete is less than the conventional concrete. But the 28 yearss strength of concrete incorporating 20 % of GGBFS is more every bit compared to conventional concrete.i.e optimal per centum of GGBFS for compaction is 20 % as shown in the graph.

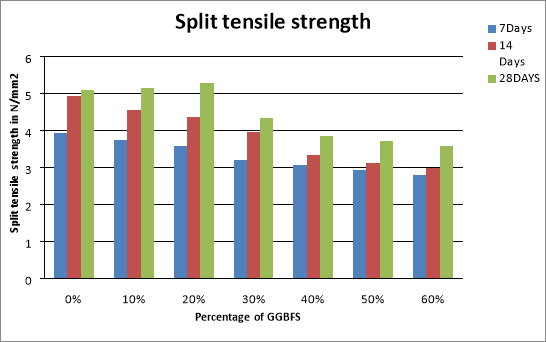

Split Tensile Strenth

Graph-2 Split tensile strength of concrete at 7,14 and 28 yearss

It is really hard to mensurate the tensile strength of the concrete straight, so it measured indirectly by puting the cylinder specimen horizontally and so using the compaction load..Here the 28 yearss tensile strength of concrete incorporating 20 % of GGBFS is more every bit compared to conventional concrete as shown in graph

Flexural Strength

Graph-3 Flexural strength of concrete at7,14 and 28 yearss

One of the chief standards to cognize the mechanical belongingss of concrete is flexural strength, in this instance trial is conducted for the concrete incorporating assorted per centums of land granulated blast furnace. Here the 7 and 14 yearss flexural strength of the concrete incorporating GGBFS for all doses is less than the conventional concrete. But the 28 yearss strength of concrete incorporating 20 % of GGBFS is more than the conventional concrete.

as shown in the graph

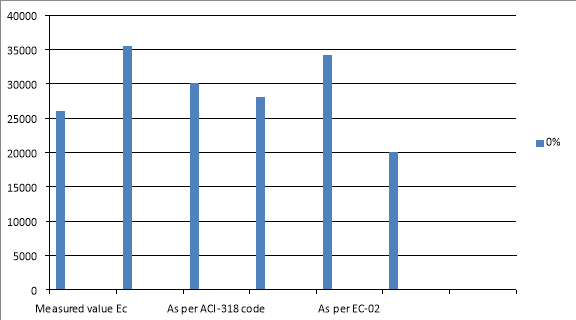

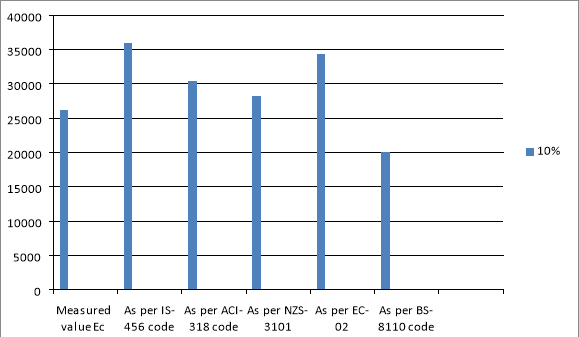

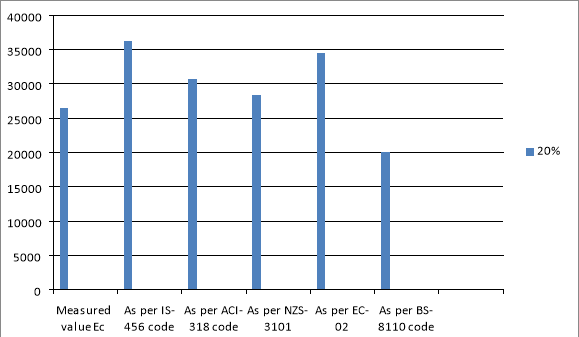

Static Modules of Elasticity

Modulus of snap of concrete is a cardinal factor for gauging the distortion of edifices and members, every bit good as a cardinal factor for finding modular ratio, which is used for the design of subdivision of members subjected to flection. It is often expressed in footings of compressive strength.

Table-15 Comparison of codal proviso for inactive modulus of snap Ec in N/mm2

| Replacement of GGBFS, % | Asper Measured value, Ec | Asper IS-456 codification | Asper ACI:318 codification | Asper New Zealand codification NZS:3101 | Asper Euro codification EC:02 | Asper BS:8110 |

| 0 | 25998.43 | 35594.94 | 30141.86 | 28038.78 | 34208.69 | 20010.14 |

| 10 | 26203.50 | 35940.92 | 30437.82 | 28246.33 | 34393.74 | 20010.33 |

| 20 | 26428.39 | 36245.68 | 30694.43 | 28426.30 | 34553.99 | 20010.51 |

| 30 | 25263.30 | 35024.99 | 29662.20 | 27702.39 | 33908.34 | 20009.81 |

| 40 | 24105.80 | 33893.21 | 28702.25 | 27029.17 | 33305.60 | 20009.20 |

| 50 | 23602.66 | 32469.22 | 27497.98 | 26184.60 | 32546.62 | 20008.43 |

| 60 | 23101.53 | 31503.96 | 26678.93 | 25610.19 | 32028.81 | 20007.94 |

Comparisons of inactive modulus of snap obtained by experimentation and that obtained from utilizing empirical looks given design codification of assorted state for both conventional concrete and GGBFS concrete is presented in the above tabular array.

Comparisons of inactive modulus of snap obtained by experimentation and that obtained from utilizing empirical looks given design codification of assorted state for both conventional concrete and GGBFS concrete is presented in the above tabular array.

Graph-4 consequences of modulus of snap as per different codifications for 0 % replacing of GGBFS

Graph-5 consequences of modulus of snap as per different codifications for 10 % replacing of GGBFS

Graph-6results of modulus of snap as per different codifications for 20 % replacing of GGBFS

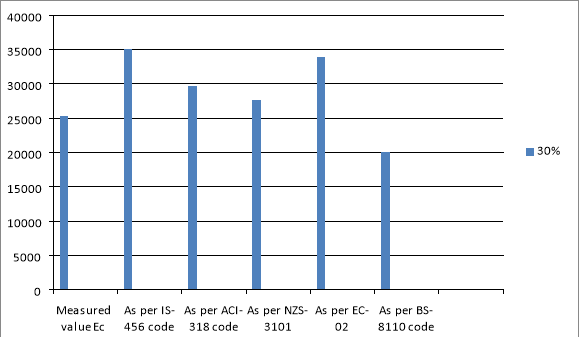

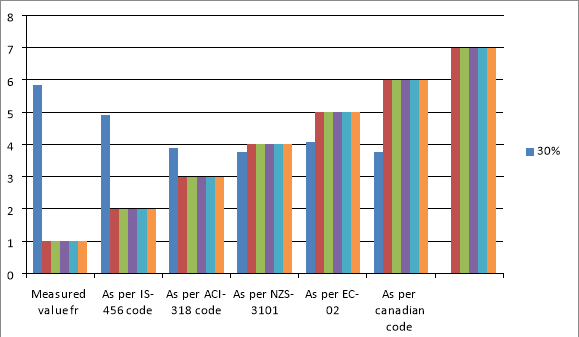

Graph-7 consequences of modulus of snap as per different codifications for 30 % replacing of GGBFS

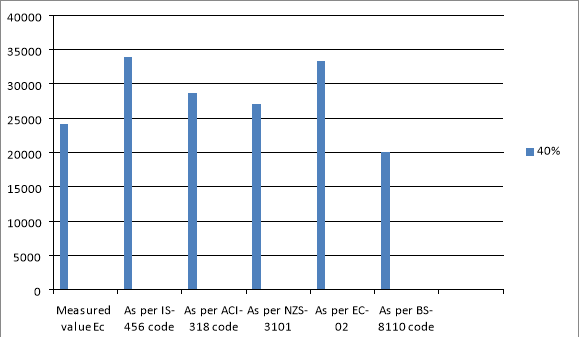

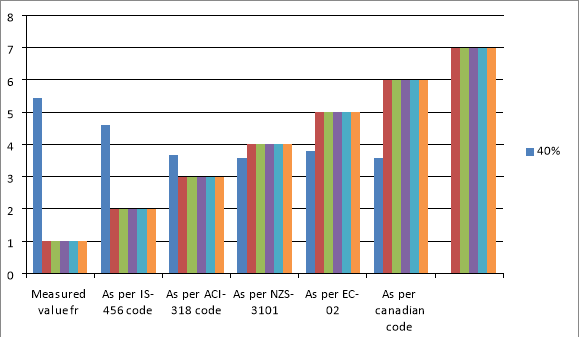

Graph-8 consequences of modulus of snap as per different codifications for 40 % replacing of GGBFS

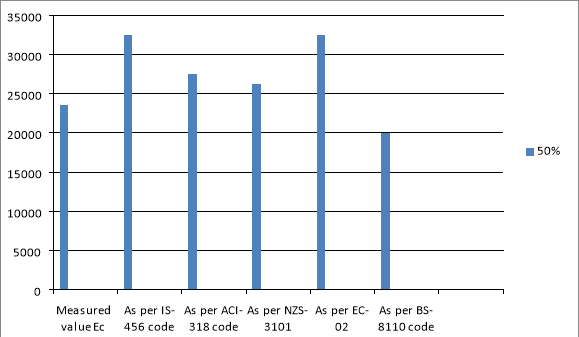

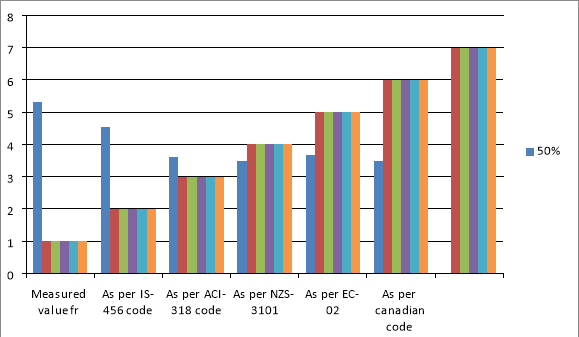

Graph-9 consequences of modulus of snap as per different codifications for 50 % replacing of GGBFS

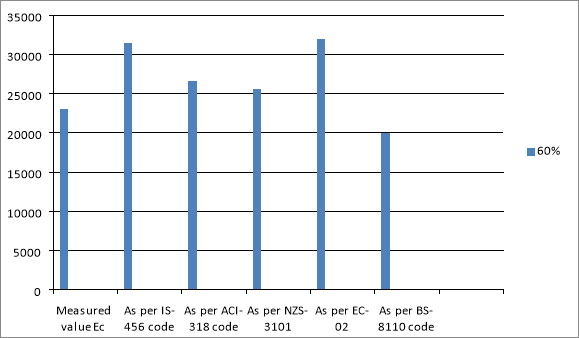

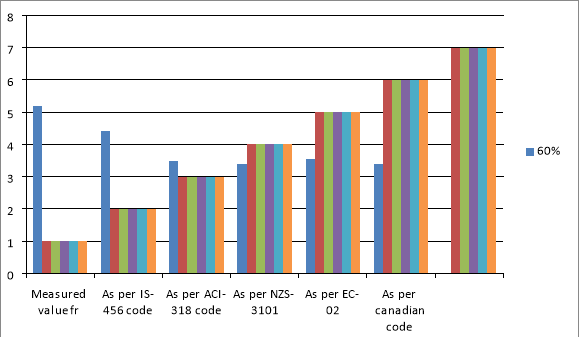

Graph-10 consequences of modulus of snap as per different codifications for 60 % replacing of GGBFS

Graph-11 consequences of modulus of snap as per different codifications

The fig shows that the inactive modulus of snap predicted by Indian codification IS:456-2000 and euro codification EC:02 are higher than those predicted by American codification ( ACI:318 ) , New Zealand codification ( NZS:3101 ) and British codification ( BS:8110 ) .

Fig besides shows that by experimentation measured modulus of snap is higher than the British codification ( BS:8110 ) and relatively lower than all other design codifications.

Table -16 Constants for empirical relationship between inactive modulus of snap and compressive strength ( C1for regular hexahedron compressive strength )

| Replacement of GGBFS, % | Asper Measured value, Ec | Asper IS-456 codification | Asper ACI:318 codification | Asper New Zealand codification NZS:3101 | Asper Euro codification EC:02 | Asper BS:8110 |

| 0 | 3652.20 | 5000.71 | 4234.03 | 3938.59 | 4805.27 | 2810.81 |

| 10 | 3655.65 | 5001.26 | 4234.72 | 3930.06 | 4784.24 | 2783.80 |

| 20 | 3658.80 | 5002.66 | 4234.98 | 3931.50 | 4766.63 | 2760.39 |

| 30 | 3611.71 | 5001.10 | 4234.50 | 3987.52 | 4839.40 | 2856.50 |

| 40 | 3570.03 | 5000.80 | 4234.44 | 4034.59 | 4963.87 | 3018.15 |

| 50 | 3541.82 | 5000.45 | 4234.32 | 4062.49 | 5010.90 | 3081.20 |

| 60 | 3551.82 | 5000.20 | 4233.11 | 4086.36 | 5083.29 | 3175.46 |

Table-17 Constants for empirical relationship between inactive modulus of snap and compressive strength ( C2 for cylinder compressive strength )

| Replacement of GGBFS, % | Asper Measured value, Ec | Asper IS-456 codification | Asper ACI:318 codification | Asper New Zealand codification NZS:3101 | Asper Euro codification EC:02 | Asper BS:8110 |

| 0 | 4075.44 | 5590.40 | 4734.40 | 4403.69 | 5329.25 | 3142.73 |

| 10 | 4076.04 | 5591.22 | 4734.85 | 4384.88 | 5312.34 | 3112.22 |

| 20 | 4083.24 | 5591.70 | 4735.28 | 4385.95 | 5299.85 | 3086.30 |

| 30 | 4063.40 | 5590.35 | 4733.65 | 4420.84 | 5410.40 | 3193.52 |

| 40 | 4031.94 | 5589.97 | 4733.90 | 4367.92 | 5492.33 | 3300.14 |

| 50 | 3985.65 | 5589.80 | 4733.40 | 4361.10 | 5612.35 | 3444.62 |

| 60 | 3910.90 | 5589.40 | 4732.99 | 4360.20 | 5683.51 | 3550.30 |

Based on the arrested development analysis of the by experimentation obtained trial consequences, the proposed correlativity of the modulus of snap and compressive strength of cylinder and regular hexahedron for conventional and GGBFS based concrete are given below

For regular hexahedron compressive strength:

Ec=C1 degree Fahrenheitdegree Celsiuss

degree Fahrenheitdegree Celsiuss

For cylinder compressive strength:

Ec=C2 degree Fahrenheitdegree Celsiuss’

degree Fahrenheitdegree Celsiuss’

Where,

TocopherolCis the inactive modulus of snap at 28 yearss in Mpa.

is the regular hexahedron compressive strength of concrete at 28 yearss Mpa.

is the regular hexahedron compressive strength of concrete at 28 yearss Mpa.

is the cylinder compressive strength at 28 yearss in Mpa.

is the cylinder compressive strength at 28 yearss in Mpa.

C1, C2Constants given in tabular array

Modulus of Rupture

Modulus of rupture is defined as a stuff ‘s ability to defy distortion under burden The Modulus of rupture represents the highest emphasis experienced within the stuff at its minute of rupture.

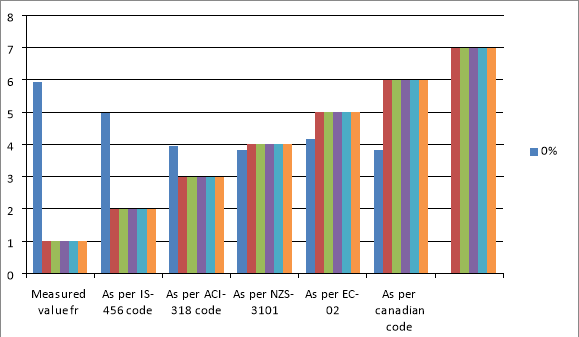

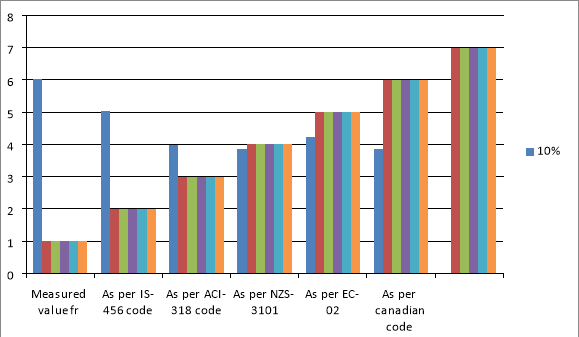

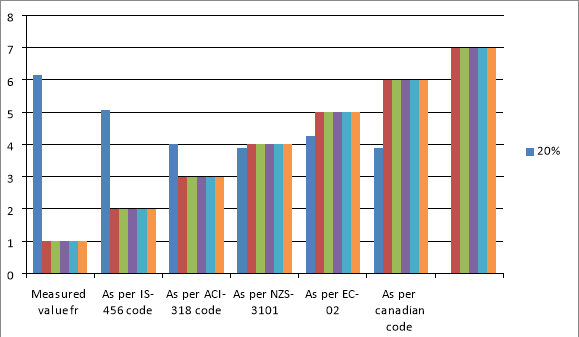

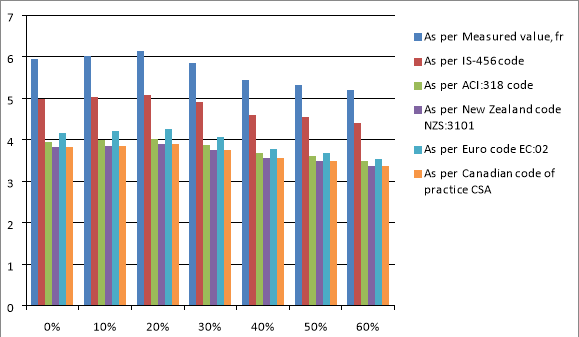

Table -18 Comparison of codal proviso for flexural tensile strength concrete Fr in N/mm2

| Replacement of GGBFS, % | Asper Measured value, Ec | Asper IS-456 codification | Asper ACI:318 codification | Asper New Zealand codification NZS:3101 | Asper Euro codification EC:02 |

Asper Canadian codification of pattern CSA

|

| 0 | 5.94 | 4.983 | 3.947 | 3.820 | 4.162 | 3.820 |

| 10 | 2021.03 | 5.031 | 3.986 | 3.857 | 4.216 | 3.857 |

| 20 | 6.15 | 5.074 | 4.019 | 3.890 | 4.265 | 3.890 |

| 30 | 5.85 | 4.903 | 3.885 | 3.759 | 4.074 | 3.759 |

| 40 | 5.45 | 4.606 | 3.676 | 3.567 | 3.783 | 3.567 |

| 50 | 5.32 | 4.545 | 3.601 | 3.485 | 3.680 | 3.485 |

| 60 | 5.19 | 4.410 | 3.494 | 3.380 | 3.534 | 3.380 |

Comparisons of flexural strength or modulus of rupture obtained by experimentation and that obtained from utilizing empirical looks given design codification of assorted state for both conventional concrete and GGBFS concrete is presented in the above tabular array

Graph-12consequences of modulus of rupture as per different codifications for 0 % replacing of GGBFS

Graph-13consequences of modulus of rupture as per different codifications for 10 % replacing of GGBFS

Graph-14 consequences of modulus of rupture as per different codifications for 20 % replacing of GGBFS

Graph-15 consequences of modulus of rupture as per different codifications for 30 % replacing of GGBFS

Graph-16consequences of modulus of rupture as per different codifications for 40 % replacing of GGBFS

Graph-17 consequences of modulus of rupture as per different codifications 50 % replacing of GGBFS

Graph-18consequences of modulus of rupture as per different codifications for 60 % replacing of GGBFS

Graph-19 consequences of modulus of rupture as per different codifications

From the fig it can be noticed that by experimentation measured modulus of rupture is higher than the IS-456 codification, ACI:318 codification, NZS:3101 codification, EC:02 codification and Canadian codification.

The below tabular array shows the inside informations of empirical relationship between modulus of rupture V regular hexahedron compressive strength and modulus of rupture V cylinder compressive strength severally

Table -19 Constants for empirical relationship between flexural tensile strength and compressive strength in N/mm2( C1 for regular hexahedron compressive strength )

| Replacement of GGBFS, % | Asper Measured value, Ec | Asper IS-456 codification | Asper ACI:318 codification | Asper New Zealand codification NZS:3101 | Asper Euro codification EC:02 |

Asper Canadian codification of pattern CSA

|

| 0 | 0.8340 | 0.6998 | 0.5545 | 0.5370 | 0.5846 | 0.5368 |

| 10 | 0.8388 | 0.6998 | 0.5545 | 0.5365 | 0.5865 | 0.5369 |

| 20 | 0.8483 | 0.6998 | 0.5545 | 0.5370 | 0.5880 | 0.5371 |

| 30 | 0.8351 | 0.6998 | 0.5545 | 0.5366 | 0.5816 | 0.5366 |

| 40 | 0.8240 | 0.6998 | 0.5545 | 0.5380 | 0.5706 | 0.5363 |

| 50 | 0.8230 | 0.6998 | 0.5545 | 0.5367 | 0.5667 | 0.5360 |

| 60 | 0.8237 | 0.6998 | 0.5545 | 0.5360 | 0.5608 | 0.5355 |

Table-20 Constants for empirical relationship between flexural tensile strength and compressive strength in N/mm2( C2 for cylinder compressive strength )

| Replacement of GGBFS, % | Asper Measured value, Ec | Asper IS-456 codification | Asper ACI:318 codification | Asper New Zealand codification NZS:3101 | Asper Euro codification EC:02 |

Asper Canadian codification of pattern CSA

|

| 0 | 0.9330 | 0.7825 | 0.6199 | 0.5999 | 0.650 | 0.5999 |

| 10 | 0.9378 | 0.7825 | 0.6199 | 0.5999 | 0.652 | 0.5999 |

| 20 | 0.9485 | 0.7830 | 0.6199 | 0.5999 | 0.657 | 0.5999 |

| 30 | 0.9336 | 0.7825 | 0.6199 | 0.5999 | 0.641 | 0.5999 |

| 40 | 0.9190 | 0.7825 | 0.6199 | 0.5999 | 0.637 | 0.5999 |

| 50 | 0.9158 | 0.7825 | 0.6199 | 0.5999 | 0.634 | 0.5999 |

| 60 | 0.9209 | 0.7825 | 0.6199 | 0.5990 | 0.627 | 0.5990 |

Based on the arrested development analysis of the by experimentation obtained trial consequences, the proposed correlativity of the flexural strength and compressive strength of cylinder and regular hexahedron for conventional and GGBFS based concrete are given below

For regular hexahedron compressive strength:

degree FahrenheitR=C1 degree Fahrenheitdegree Celsiuss

degree Fahrenheitdegree Celsiuss

For cylinder compressive strength:

degree FahrenheitR=C2 degree Fahrenheitdegree Celsiuss’

degree Fahrenheitdegree Celsiuss’

Where,

. is modulus of rupture of concrete at 28 yearss in Mpa

is modulus of rupture of concrete at 28 yearss in Mpa

is the regular hexahedron compressive strength of concrete at 28 yearss Mpa.

is the regular hexahedron compressive strength of concrete at 28 yearss Mpa.

is the cylinder compressive strength at 28 yearss in Mpa.

is the cylinder compressive strength at 28 yearss in Mpa.

C1, C2Constants given in tabular array

Decision

Following decisions were drawn from this experimental work.

- The 7 yearss and 14days compressive strength, Tensile strength and flexural strength of GGBFS concrete is less than the apparent concrete but the 28 yearss strength of the GGBFS concrete with 20 % replacing is more than kick concrete farther the add-on of GGBFS will diminish the strength.i.e optimal replacing per centum of GGBFS by weight of cement is up to 20 % .

- The by experimentation measured values of modulus of snap of GGBFS Concrete are lower as compared to Indian codification IS:456-2000 and euro codification EC:02, American codification

( ACI:318 ) and New Zealand codification ( NZS:3101 ) .

- The inactive modulus of snap predicted by Indian codification IS:456-2000 and euro codification EC:02 are higher than those predicted by American codification ( ACI:318 ) , New Zealand codification ( NZS:3101 ) and British codification ( BS:8110 ) .

- The by experimentation mensural modulus of snap is higher than the British codification ( BS:8110 ) and relatively lower than all other design codifications.

- The by experimentation mensural modulus of rupture is higher than the IS-456 codification, ACI:318 codification, NZS:3101 codification, EC:02 codification and Canadian codification.

- The new empirical dealingss for inactive modulus of snap flexural tensile strength or.modulus of rupture and compressive strength of concrete integrating different per centum of GGBFS in apparent concrete are proposed

.