Partitions are the perpendicular walls or panels that are used to split parts of the edifice and they can be classified as burden bearing or non-load bearing. Traditionally timber was used as dividers but with the promotion in building methods and the usage of light weight breakdown and light weight insularity block, its usage as a divider is diminishing significantly.

Partitions can be constructed utilizing assorted stuffs, but the most common types of dividers are:

- Timber Stud Partitions.

- Metal Stud or Dry wall Partitions.

- Glass Partitions.

- Skiding Partitions

- Room splitters

- Re-locatable office Partitions

Timber Stud Partition

Timber stud dividers are non-load bearing and light weight dividers. Timber stud dividers consist of wooden model between horizontal caput and exclusive pieces at the top and underside of the model and a series of verticals called studs keeping the whole model. The noggings are intermediate stiffening stuff placed between the he-man to guarantee the overall stableness of the model. Timber frame dividers are formed with butt articulations or bordering ground tackles to significantly ease the low labor cost and velocity of hard-on. Plasterboard is normally used as a covering stuff for lumber dividers.

Metal Stud or Dry wall Partitions

Metal he-man dividers are non-load bearing dividers dwelling of a metal doting model. This metal doting makes the dividers light weight but relatively strong and stable than timber stud dividers. They can be covered with ordinary gypsum boards or particular fire immune sheets, which on concluding waterproofing can do these dividers sound cogent evidence every bit good as fire resistant.

Metal stud dividers are speedy and easy to raise, they are cost effectual, sustainable for all types of edifices and they are available in assortment of coatings. Due to these strong features metal he-man dividers are largely used in public edifices and infirmaries. The metal he-man are manufactured from galvanised steel sheet folded into assorted molded subdivisions which slot into each other. The subdivisions are produced in assorted lengths runing from 2.4 m to 6 m in length and breadths runing from 50 millimeters to 146 millimeters.

Glass dividers

Glass fulfils an of import function in making divisions between indoors and out every bit good as between single interior infinites. The proficient progresss in the stuff mean that it is suited for a wider scope of applications than of all time before.

Single glazing can be used where clean lines and an aesthetically pleasing design are indispensable. The breakdown is designed with the minimal sum of model to give a frameless visual aspect. To keep the unfastened feel of the office environment frameless doors or framed glass doors are fitted within the system utilizing floor pivots and piece adjustments or floor springs if required.

Where desired or in order to follow with edifice ordinances, to the full glazed panels have manifestation movie applied to them. These can be used to merely foreground the presence of the dividers, create single designs or integrate company logos utilizing either 10/12mm toughened glass depending on the tallness of the divider, glazing is achieved with the usage of clear glazing gaskets that remove the demand for silicone around the margin of the system.

Vertical silicone articulations maintain the ocular simpleness of the merchandise or clear plastic jointing subdivisions to supply dry articulations between glass panels.

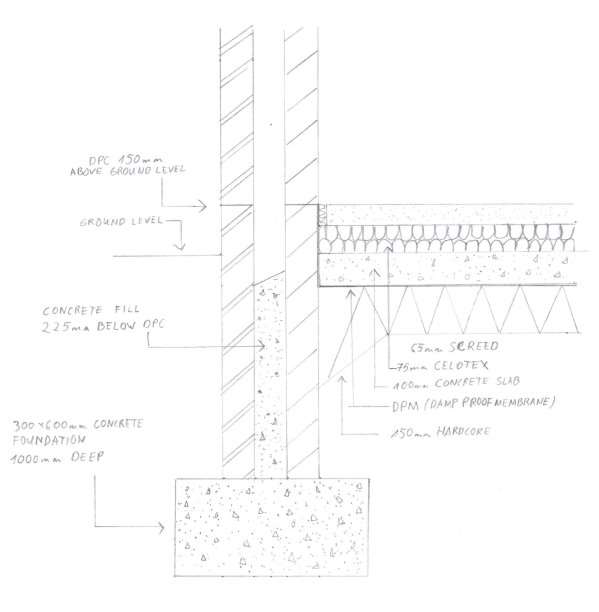

Appendix 1

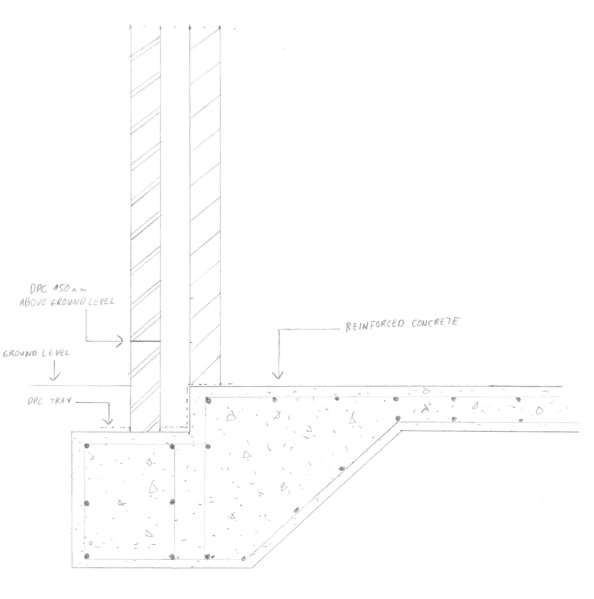

Traditional strip foundations

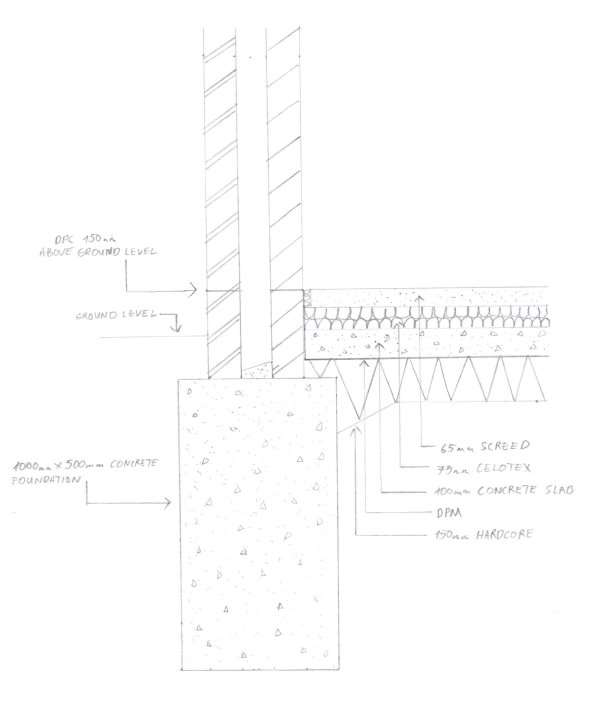

Appendix 2

Trench fill foundations

Appendix 3

Raft foundations

Appendix 4

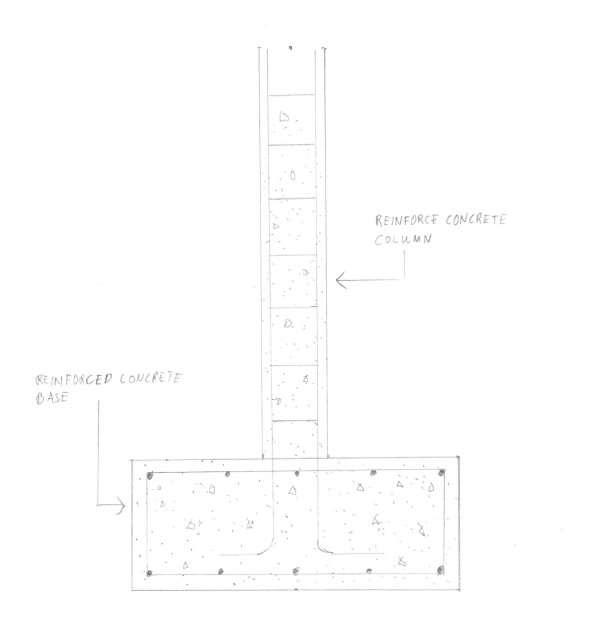

Pad foundations

Appendix 5

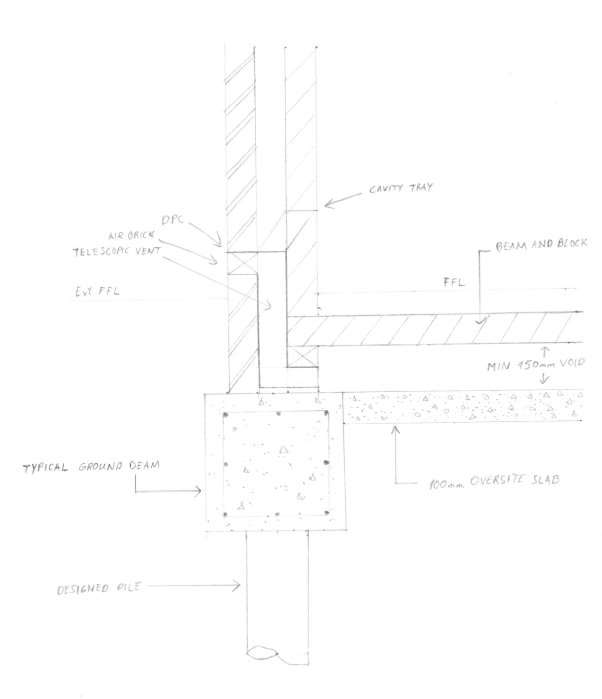

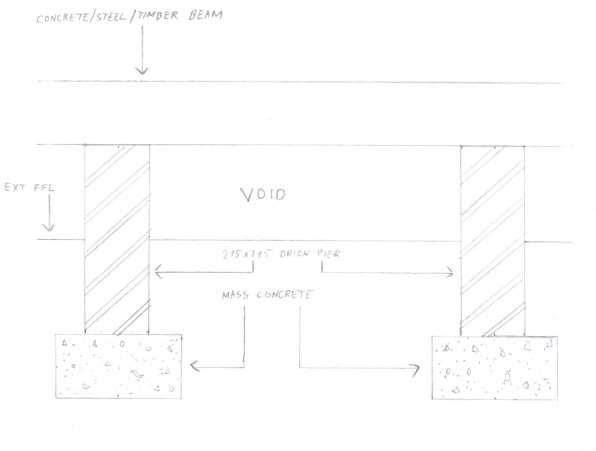

Pier and beam foundations

Appendix 6

Pile foundations